Various applications of pipe elbows are as follows: They are manufactured to be used in flow lines for gases, fluids in industrial processes, medical, construction and many other specialized applications.

The elbows are constructed of heavy materials for rigid applications like extreme high/low temperature resistance etc.

The elbows are specifically designed for use on process and control systems, instrumentation, and equipment used in chemical, petroleum, fluid power, electronic and pulp and paper plants.

All our products are packed, stored, transported according to the international regulation. The elbows are wrapped with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.Ply wooden box are available for special protection. Other kinds of packing can be offered if request.

|

Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

201 |

≤0.15 |

≤0.75 |

5.5-7.5 |

≤0.06 |

≤0.03 |

3.5-5.5 |

16.0-18.0 |

- |

|

202 |

≤0.15 |

≤1.0 |

7.5-10.0 |

≤0.06 |

≤0.03 |

4.-6.0 |

17.0-19.0 |

- |

|

301 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

6.0-8.0 |

16.0-18.0 |

- |

|

302 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

8.0-10.0 |

17.0-19.0 |

- |

|

304 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

8.0-10.5 |

18.0-20.0 |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

9.0-13.0 |

18.0-20.0 |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

12.0-15.0 |

22.0-24.0 |

- |

|

310S |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.035 |

≤0.03 |

19.0-22.0 |

24.0-26.0 |

- |

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

316L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

12.0-15.0 |

16.0-18.0 |

2.0-3.0 |

|

321 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

9.0-13.0 |

17.0-19.0 |

- |

|

630 |

≤0.07 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

3.0-5.0 |

15.5-17.5 |

- |

|

631 |

≤0.09 |

≤1.0 |

≤1.0 |

≤0.030 |

≤0.035 |

6.50-7.75 |

16.0-18.0 |

- |

|

904L |

≤2.0 |

≤0.045 |

≤1.0 |

≤0.035 |

- |

23.0-28.0 |

19.0-23.0 |

4.0-5.0 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.030 |

≤0.02 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

|

2507 |

≤0.03 |

≤0.80 |

≤1.2 |

≤0.035 |

≤0.02 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

|

2520 |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.045 |

≤0.03 |

0.19-0.22 |

0.24-0.26 |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

- |

11.5-13.5 |

- |

|

430 |

≤0.12 |

≤0.75 |

≤1.0 |

≤0.040 |

≤0.03 |

≤0.60 |

16.0-18.0 |

- |

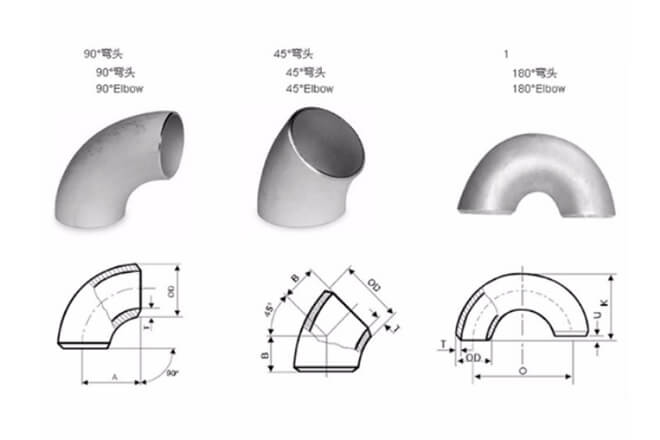

45°elbow / 90°elbow / 180°elbow

SR (Short Radius) elbows and LR (Long Radius) elbows

Butt welded / Socket / Threaded

A reducer is the component in a pipeline that reduces the pipe size from a larger to a smaller bore (inner diameter).

The length of the reduction is usually equal to the average of the larger and smaller pipe diameters.

There are two main types of reducer: concentric and eccentric reducers.

1)3a-Welded reducer

|

Size |

A |

D |

T |

T1 |

|

1.5*1.0" |

50.8 |

38.1 |

1.65 |

1.65 |

|

2.0*1.0" |

101.6 |

50.8 |

1.65 |

1.65 |

|

2.0*1.5" |

50.8 |

50.8 |

1.65 |

1.65 |

|

2.5*1.5" |

101.6 |

63.5 |

1.65 |

1.65 |

|

2.5*2.0" |

50.8 |

63.5 |

1.65 |

1.65 |

|

3.0*1.5" |

152.4 |

76.2 |

1.65 |

1.65 |

|

3.0*2.0" |

101.6 |

76.2 |

1.65 |

1.65 |

|

3.0*2.5" |

50.8 |

76.2 |

1.65 |

1.65 |

|

4.0*1.5" |

254 |

101.6 |

2.1 |

1.65 |

|

4.0*2.0" |

203.2 |

101.6 |

2.1 |

1.65 |

|

4.0*2.5" |

152.4 |

101.6 |

2.1 |

1.65 |

|

4.0*3.0" |

101.6 |

101.6 |

2.1 |

1.65 |

|

6.0*3.0" |

140.0 |

152.4 |

2.8 |

1.65 |

|

6.0*4.0" |

140.0 |

152.4 |

2.8 |

2.1 |

|

Size |

A |

A1 |

D |

D2 |

D2 |

|

38*25 1.5*1.0" |

39 |

46 |

38.1 |

25.4 |

0.062 |

|

51*25 2.0*1.0" |

57 |

68 |

50.8 |

25.4 |

0.125 |

|

51*38 2.0*1.5" |

39 |

47 |

50.8 |

38.1 |

0.086 |

|

63*25 2.5*1.0" |

74 |

92 |

63.5 |

25.4 |

0.243 |

|

63*30 2.5*1.5" |

57 |

70 |

63.5 |

38.1 |

0.214 |

|

63*51 2.5*2.0" |

39 |

44 |

63.5 |

50.8 |

0.134 |

|

76*25 3.0*1.0“ |

92 |

117 |

76.2 |

25.4 |

0.382 |

|

76*38 3.0*1.5” |

74 |

92 |

76.2 |

38.1 |

0.321 |

|

76*51 3.0*2.0" |

57 |

68 |

76.2 |

50.8 |

0.251 |

|

76*63 3.0*2.5" |

39 |

47 |

76.2 |

63.5 |

0.173 |

|

101.6*51 4.0*2.0" |

95 |

117 |

101.6 |

50.8 |

0.563 |

|

101.6*63.5 4.0*2.5" |

78 |

94 |

101.6 |

63.5 |

0.521 |

|

101.6*76.1 4.0*3.0" |

60 |

74 |

101.6 |

76.2 |

0.39 |

|

127*63.5 5.0*2.5 |

137 |

167 |

127 |

63.5 |

0.65 |

|

127*76 5.0*3 |

137 |

467 |

127 |

76 |

0.60 |

|

127*102 5.0*4 |

152 |

161 |

127 |

102 |

0.9 |

|

152.4*76 6.0*4 |

140 |

170 |

152 |

76 |

1.10 |

|

152.4*102 6.0*5 |

140 |

170 |

152 |

102 |

1.2 |

|

152.4*127 |

102 |

126 |

152 |

127 |

0.75 |

|

Size |

A |

T |

T1 |

D |

D2 |

|

20*15 |

7 |

1.5 |

1.5 |

22 |

18 |

|

25*20 |

11 |

1.5 |

1.5 |

28 |

22 |

|

32*20 |

22 |

1.5 |

1.5 |

34 |

22 |

|

32*25 |

11 |

1.5 |

1.5 |

34 |

28 |

|

40*20 |

33 |

1.5 |

1.5 |

40 |

22 |

|

40*25 |

22 |

1.5 |

1.5 |

40 |

28 |

|

40*32 |

11 |

1.5 |

1.5 |

40 |

34 |

|

50*25 |

44 |

1.5 |

1.5 |

52 |

28 |

|

50*32 |

33 |

1.5 |

1.5 |

52 |

34 |

|

50*40 |

22 |

1.5 |

1.5 |

52 |

40 |

|

65*25 |

73 |

2 |

1.5 |

70 |

28 |

|

65*32 |

62 |

2 |

1.5 |

70 |

34 |

|

65*40 |

51 |

2 |

1.5 |

70 |

40 |

|

65*505 |

29 |

2 |

1.5 |

70 |

52 |

|

80*40 |

78 |

2 |

1.5 |

85 |

70 |

|

80*50 |

56 |

2 |

1.5 |

85 |

52 |

|

80*65 |

27 |

2 |

2 |

85 |

70 |

|

100*50 |

90 |

2 |

1.5 |

104 |

85 |

|

100*65 |

61 |

2 |

2 |

104 |

70 |

|

100*80 |

34 |

2 |

2 |

104 |

85 |

|

125*65 |

105 |

2 |

2 |

129 |

104 |

|

125*80 |

80 |

2 |

2 |

129 |

85 |

|

125*100 |

45 |

2 |

2 |

129 |

104 |

|

150*80 |

120 |

2 |

2 |

154 |

85 |

|

150*100 |

90 |

2 |

2 |

154 |

104 |

|

150*125 |

90 |

2 |

2 |

154 |

129 |